When you are out on the water and you “gotta go” a marine plumbing system is a welcome sight aboard a vessel. In this situation the “going” is the easy part. Using the head properly and regularly maintaining all associated parts from the head to the holding tanks to the discharge requires education, attention, and grit. In this case, more so than any other, misuse or neglect will, quite literally, stink.

While there are different types of marine plumbing systems, the focus of this article is on marine heads with holding tanks. This system follows a basic trajectory: The head is used, the holding tank collects waste, and the waste is disposed of either offshore or at a designated pump out facility. The US Coast Guard requires all freshwater and saltwater boaters within three miles of shore to dispose of marine sanitation waste at proper pump-out facilities. Boaters that travel in and out of this zone will have a Y valve in their system that allows them to dispose of their waste responsibly depending on where they are. A macerator pump, though not required, is useful in this system as it mascerates or mashes to a pulpy liquid the waste either before it enters the holding tanks or after leaving the holding tanks before discharge exits the boat.

Education about using the head properly is the first step in maintaining a boat’s plumbing system well. To start, a captain is wise to discuss with all crew and guests the workings of the boats’ specific sanitation system. It is additionally helpful to have step by step instructions, no matter how cheeky or elemental, posted in the lavatory for all users to refer to. Some of the instructions will be universal including:

- The details and procedure for getting water into the bowl before depositing solid waste.

- The use and disposal of a small amount of single-ply, readily dissolvable toilet paper.

- What goes in the trash bin without exception: Human waste only.

- The procedure for flushing the waste.

Some of these instructions will be head specific. For example, some heads require a user to turn a valve to fill and flush by pumping manually. Other heads require a user to push specific buttons for different levels of filling and flushing. Users that know the specific process and requirements for the head they will be using are more likely to use the head without a problem.

*Universal Stench Tip: If possible, freshwater rinsing the bowl of the head after each use can lessen the stench that comes with marine heads and holding tanks. Microorganisms in sea water combine with waste in tanks and can ripen an otherwise ripe environment. However, not all boats have that much freshwater to spare and therefore flush using raw sea water. Try spraying the bowl with a water/vinegar (7:1) solution after each use. This keeps build up in the bowl at bay while neutralizing the aforementioned odors.

After care is taken to ensure that the marine head is used properly, one must turn their attention to maintaining the head and holding tanks themselves. Mind you, this takes grit. Always, refer to the head owners manual detailed instructions for specific head troubleshooting and maintenance. That said, here are 7 universal maintenance tips.

- Inspect the tanks, hoses, and hose clamps for leaks annually or as needed. Watertight integrity is key!

Metal tanks are especially at risk for becoming leaky as liquid waste acids will literally eat holes in metal tanks. Fiberglass tanks can blister. Thick-walled plastic tanks that are welded in fabrication can leak at the welds. Hose clamps need to be uncompromised by any corrosion and tight.

- Know your tank capacity and monitor holding tanks levels

Knowing how much typical use fills the tanks is important particularly should the tanks begin to fill at an unusual rate. This can indicate a float switch malfunction, a buildup that is constricting the holding tanks available space or worse, a leak that is allowing the tank to appear ‘bottomless’.

- Pump out before the holding tanks are full.

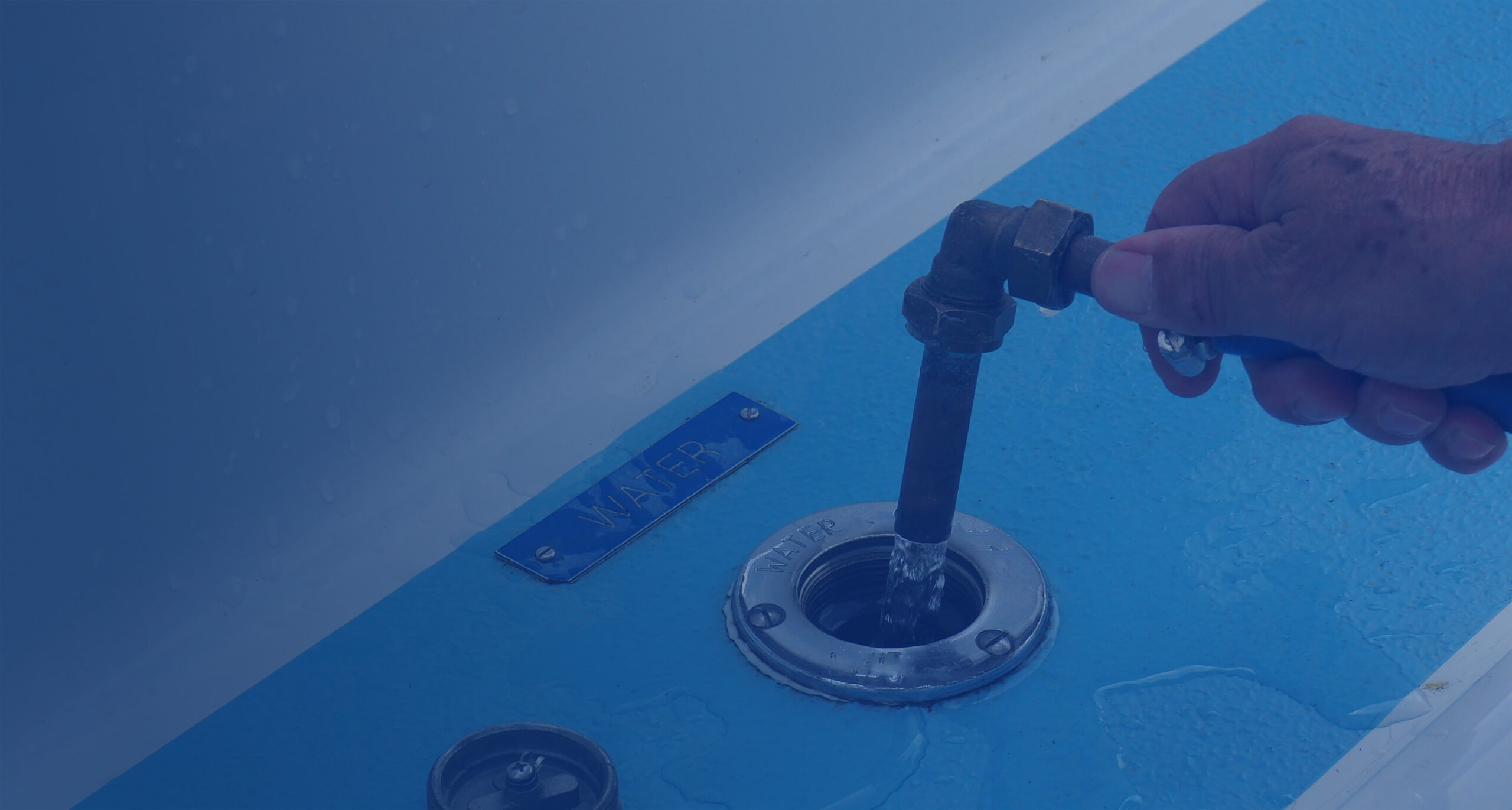

Empty the holding tanks in port at a proper pump-out station using your deck vacuum fitting. When a holding tank is full it can no longer accept any waste. No more waste can be held leaving waste either standing in the bowl of the head, in the hoses, or worse bubbling out of the vent. This is best absolutely avoided.

- Freshwater flush the holding tanks.

- Ideally, flush the holding tanks every time the holding tanks are pumped out. Alternatively, do this every other time or thereabouts. Simply put, the more regularly holding tanks are flushed and washed, the less sludge and solids will build up inside them.

- To flush, some boaters will fill the holding tank through the deck discharge with a freshwater deck hose and pump the holding tanks again. Other boaters will fill the head bowl with sea water or fresh water 1-5 times, pump this into the holding tank, and pump the holding tank again. Before leaving the pump out station, some boat owners will put a small amount of freshwater in their holding tanks to slosh around on their next outing. The idea is to dislodge and/or discourage any sludge and/or solids from building up in the tanks.

- Boat owners with concerns about sludge and solid build-up in their tanks will, annually or more frequently as needed, add a large amounts of water (1-5 gallons depending on tank size), and a concoction of some or all of the following: 1-2 cups of borax*, a small amount of biodegradable, bleach-free cleaner, and some ice cubes to their holding tanks. Set out into choppy waters sloshing the mixture around in the holding tanks a bit. This process is designed to loosen sludge and debris inside holding tanks. Return to the pump out station and pump out the tanks.

*Note: when choosing Borax in your concoction, hot water is best. Never use harsh chemical drain cleaners. These can worsen build-up and corrode plumbing parts such as hoses, seals, and/or tanks.

- Pick a treatment or additive and use it regularly.

There are many different schools of thought on what treatment to pick. The most important consideration is that the treatment helps break down the solids in the tank, improves overall decomposition (digestion), and deodorizes the tanks. Some treatments are liquid and some are powders. Some are formaldehyde free, biodegradable, enzyme, probiotic, and/or bacteria based. Some are more or less harsh and difficult or easy to breathe in. We are partial to the bacteria based products that introduce probiotics into the system from the bowl through the hoses to the tanks. These microorganisms live, eat, digest, and multiply in the holding tanks. Follow the dosage and use instructions on the chosen treatment for best results.

- Lubricate pump handles and parts per manufacturer's instructions.

Use product specific lubricant. Do not use vegetable or mineral oils. These oils have been found in direct connection with solid build up in holding tanks.

- Keep a spare repair kit or two on board at all times.

The repair kit comes to the rescue when a seal or valve fails. Be aware that when the repair kit must come out, so must your grit. Don your superhero cape with or without a mask. If necessary, the best mask for this task is a true paint respirator with a 3M charcoal filter. Be sure to wear gloves and properly dispose of any used parts. With a repair kit, you can make what could be a disaster, all but a hiccup.

All in all, when it comes to marine heads and holding tanks the nose is typically the first to notice anything amiss. Marine head odor does not improve with age or welcome guests aboard. Further, heads, hoses, and holding tanks do not fix themselves. Get and stay ahead of any such problems to keep your boat cabin fresh.

Don’t let the sh*it hit the proverbial fan. Contact Ahoy! to get an insurance quote today.