Turning the key to the ignition of a Marine Diesel Engine comes with a moment of great anticipation. Perhaps you are preparing to take family or friends out on the water for the day, catch the morning bite or the sunset. Perhaps you are already off the dock, away from your home port with a lunch hook set, ready to weigh your anchor and move on. Wherever and whenever it is that you go to start your engine, every boater wants their engine to turn on with the first try without exception. Ensuring this keeps both captain and crew at ease enjoying their time on the water. At Ahoy! We understand boaters needs, as a boat insurance company built buy boaters, for boaters, we understand the need to keep a boat maintained for safety.

Understanding the basic parts, their function, and the processes at work are key to maintaining a marine diesel engine for optimal performance so that the engine starts every time and runs the distance desired.

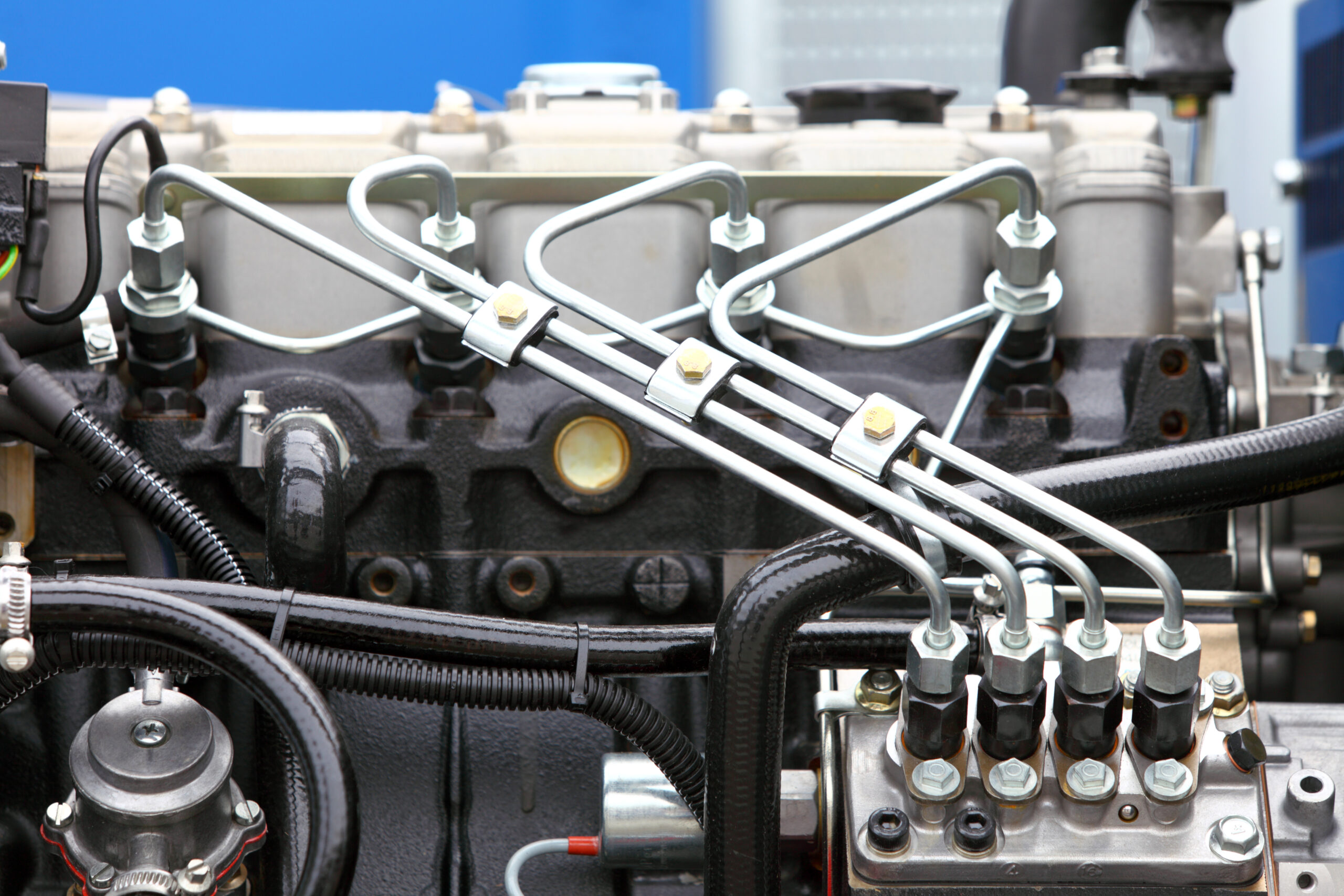

The Basic Parts in a Marine Diesel Engine:

- Starter

- Fuel tank

- Filters: fuel filters, air filters, oil filter

- Pumps: fuel, water, and oil pumps

- Injectors (one for each cylinder)

- Camshaft

- Valves and valve rockers

- Air Intake

- Exhaust outlet

- Cylinder

- Cylinder Head

- Piston

- Crankarm

- Crankshaft

- Oil Drain

When Adolf Diesel invented this engine system in the late 1800’s he designed multiple parts that move independently yet impeccably in sequence with one another to create power. Diesel engines are considered Compression Ignition (CI) Engines because their ignition and subsequent running is the result of a precisely timed fire triangle that uses compression to heat air to a temperature in which diesel fuel explodes.

Modern marine diesel engines are typically made of an even number of cylinders: 2,4,6…12 for example. The greater the number of cylinders, the greater the number of little carefully timed explosions, and the greater the capable horsepower. No matter the number of cylinders a diesel engine has the maintenance protocols and basic operations hold.

Some people use the acronym ‘WOBBLE” to drive their regular maintenance protocol and remember the key components of their regular engine checks:

W Water filter >> Keep clean

O Oil >> Keep topped up

B Belt >> Keep tight

B Bilges >> Monitor, keep clean

L Levels >> Coolant levels topped up, fuel

E Engine/exhaust >> Check for water flow

Read on to understand the basic operations of a Diesel engine and how regularly checking and maintaining these key components will keep an engine running smoothly.

Beginning at the fuel tank, diesel is pumped through a primary and then a secondary fuel filter into a high-pressure injection pump that sprays a precisely metered, fine mist through an injector into each cylinder head. The timing of this fine mist has to follow the intake of air into the cylinder and coincide with the compression of the air to the top of the cylinder head which creates the heat necessary for the diesel to explode. In order for the cycle to continue, spent combustion gases (exhaust) from the small explosion have to be released from the cylinder and pushed out the exhaust valve.

The optimal functioning of a diesel engine requires attention to 5 key areas: clean filtered fuel, air and oil, monitoring the proper timing of all moving parts and maintaining proper engine temperature. Always refer to and defer to the engine manual for maintenance and upkeep schedule. Some basic recommendations are included below:

1. Clean and Filtered Fuel:

In no uncertain terms the Ford Lehman owners manual says, “a clean fuel system is absolutely essential (requiring) scrupulous cleanliness.” Water, dirt, dust, and/or bacteria, even in microscopic amounts, can contaminate fuel, cause blockage or scoring, interrupt the precise timing, and thereby disable an engine. 9 out of 10 times diesel engine problems result from contaminated fuel.

Maintenance and upkeep:

- Use clean diesel fuel

- Replace fuel filters and associated O-rings regularly according to engine manufacturers’ instructions: every 200-300 operating hours more than likely.

- Be mindful of fuel that has been or is to be left for any length of time.

2. Clean and Filtered Air:

Clean and filtered air keeps the inside of the cylinders free of any debris that could score their inner walls and/or wear on the pistons destabilizing the pressure required for compression ignition. Damage inside the cylinders directly compromises engine performance.

Maintenance and upkeep:

- Keep air filters clean and if it is a cabin cruiser or pets are aboard, air filters should be cleaned or replaced more often.

3. Clean and Filtered Oil:

Lubricating oil for diesel engines is specially formulated to keep diesel engines running smoothly. They are formulated to keep soot from forming and gumming up pistons, valves and valve stems leading to a lowering or loss of engine efficiency. Over time the additives in the oil that keep the soot down are used up. Soot will form and parts that need to move freely get gummed up.

Maintenance upkeep:

- Before starting the engine check oil quality and top up if necessary engine oil level.

- Among the engine gauges is an oil pressure gauge. Always glance at this gauge when starting the engine as proper pressure is an indication that the moving parts are being properly lubricated while the engine is running.

- Oil changes are recommended every 100 to 200 operating hours and filters should be changed every oil change. Using High quality modern oils may accommodate longer oil change intervals.

Maintenance Regarding all types of filters:

In general, it is much easier to keep contaminants out of the system by regularly cleaning and/or changing filters than to attempt to clean contaminants out of an engine once they are inside or rectify any damage caused. Regular air, fuel, and oil filter changes are relatively simple and infinitely important.

4. Monitoring Proper Timing:

When first turning the key the starter engages the flywheel and cranks the engine. Within each cylinder there is a piston attached to a crankarm. Each crankarm is attached along the length of the crankshaft in a different position. Each position is precise so that the piston in each cylinder goes up or down. Only one piston is in the firing position at any given moment. As the crankshaft rotates each piston follows the same sequence or cycle albeit to a different time.

Meanwhile, the camshaft rotates and drives the valve rockers and the valves into alternating open and closed positions. There are two valves at the top of each cylinder. One allows air in while the other allows exhaust out of each cylinder. The rotation of the camshaft moves each valve into a particular position depending on what needs to happen in the cycle.

The cycle is as follows: the piston goes down, and air enters the cylinder through a valve in the space above the piston. The crankshaft rotates the crankarm up pushing the piston up and compressing the air up into the cylinder head. The compression creates superheated air needed to ignite and burn the diesel fuel that is injected into the cylinder head when the piston is near the top of its stroke. In an instant, this small explosion drives the piston back down in what is called the powerstroke. The crankshaft continues to rotate moving the crankarm and pushing the piston back up releasing the spent combustion gases out of the exhaust valve. The cycle within one cylinder is now complete and will repeat. Fuel continues to be filtered, pumped and sprayed one by one into each cylinder head. The crankshaft continues to rotate driving the crankarms that push and pull pistons in each cylinder. The camshaft continued to rotate driving the valve rockers and the valves to open or close moving air and exhaust in the system.

Maintenance and upkeep:

- Grease points recommended in owner’s manual to keep moving parts well lubricated

- Check belt and pulley tensions (moderate finger pressure should not exceed ½” movement)

- Check wiring connections, cables, hoses, and hose clamps.

- Check exhaust components, particularly the elbow which can corrode through. Replace as needed.

- Check engine mount bolts

5. Maintaining Proper Engine Temperature:

The heat created by compression ignition far exceeds the heat required for diesel to explode and requires constant cooling lest the engine quickly overheat. Most marine diesel engines are cooled by the circulation of coolant and raw water. Raw water is pumped past a sea strainer into the cooling system from the surrounding water. This water is circulated through heat exchangers to absorb engine heat in excess of 150 degrees (or whatever temperature the thermostat is set to). The heated raw water is sent out with the exhaust.

Maintenance and upkeep:

- Before starting the engine check and top up if necessary the water coolant level.

- Every time the engine is started, visually check the exhaust for raw water exiting in bursts.

- Clean raw water sea strainers weekly.

- Zinc Pencil, or Pencil Zincs on the heat exchanger should be inspected every 2 weeks regardless of operating hours until the owner determines the rate of electrolysis in their marine environment. Replace after 50% deterioration.

- Check the condition of coolant, hoses, and hose clamps periodically.

- Replace raw water pump impeller according to owners manual

Getting to know your engine, referring to your Owner’s Manual, and keeping up on regular maintenance and upkeep will ensure that a marine diesel engine in good working order stays in good working order.